It is our collective understanding that government desires the ability to convert flared gases into finish products, i.e. wanting to know exactly how they can profit from converted gas waste products ordinarily flared off.

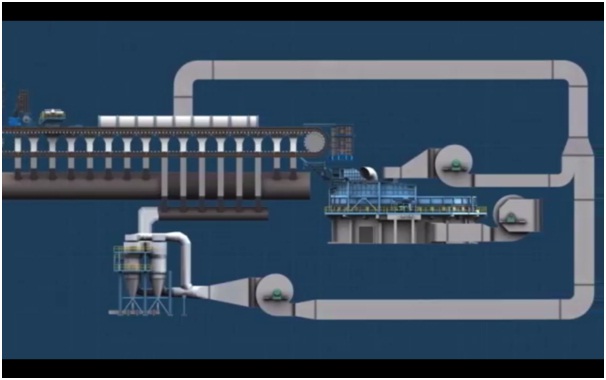

Before truly addressing specifics, we must be able to perform onsite due diligence, e.g. capture samples, geotechnical, topographical, infrastructure analysis, not to mention the four (4) factors to determine economic viability: (a) gas quality, (b) gas cost relative to goods sold / net operating income, (c) gas use rate, and (d) product value.Conceptually: The natural gas is heat cracked —produced by burning some of the natural gas to generate temperatures 2,700 –to- 3,300 degrees Fahrenheit (1,480 –to- 1,815 degrees Celsius)—into acetylene, a simple hydrocarbon. The acetylene is absorbed by a liquid solvent and then reacted to produce ethylene, a longer hydrocarbon chain that is the starting constituent of many plastics, detergents and other products. When liquid fuel is the goal, and then the ethylene is chemically bound together to form even longer hydrocarbon chains that we know as gasoline or kerosene (jet fuel), not to mention we are trying to develop process to produce diesel.

The process converts roughly 50% of the natural gas to acetylene—the other half is burned for the heat that drives the process, giving off by product emissions of only clean water and Carbon Dioxide (CO2) of which we can capture can be easily sequestered cryogenically and convert into dry ice –or- re-injected into oil wells for reservoir maintenance; and nearly all of that acetylene to ethylene, and then ethylene to fuel.

Overall conversion rates from natural gas to fuel-grade liquids are predictably 46% in optimal conditions. The resulting liquid fuel has no Sulfur; although Sulfur and Mercury are removed as solids they can be converted / sold for other useful applications. The resulting liquid fuels could be directly, i.e. fill into cars / trucks up with the liquid gas.

Nigerian oil companies flare some 850 billion cubic feet (24 billion cubic meters) per year on oil platforms, and have no need to generate electricity because of the platform's remote location and no pipelines to carry off the natural

gas—flaring is just burning money. Converting just 10% of the flared natural gas worldwide to gasoline sold at $90 per barrel would net $3.985 billion in revenue.

Depending on the quality of the natural gas itself, the process can then make gasoline at a cost of roughly $31 to $63 per barrel (approximately 73 cents to $1.50 per gallon), depending on whether the natural gas is pure methane (more costly to transform) or has other hydrocarbons mixed in.

We are making ongoing investments into advancing concepts due diligence, and perfecting commercial capabilities. Working with strategic and regional tactical partners, we plan to grow our business virally, we will apply different regional and business conditions, business development and working economic models will be employed to satisfy our viability calculus.